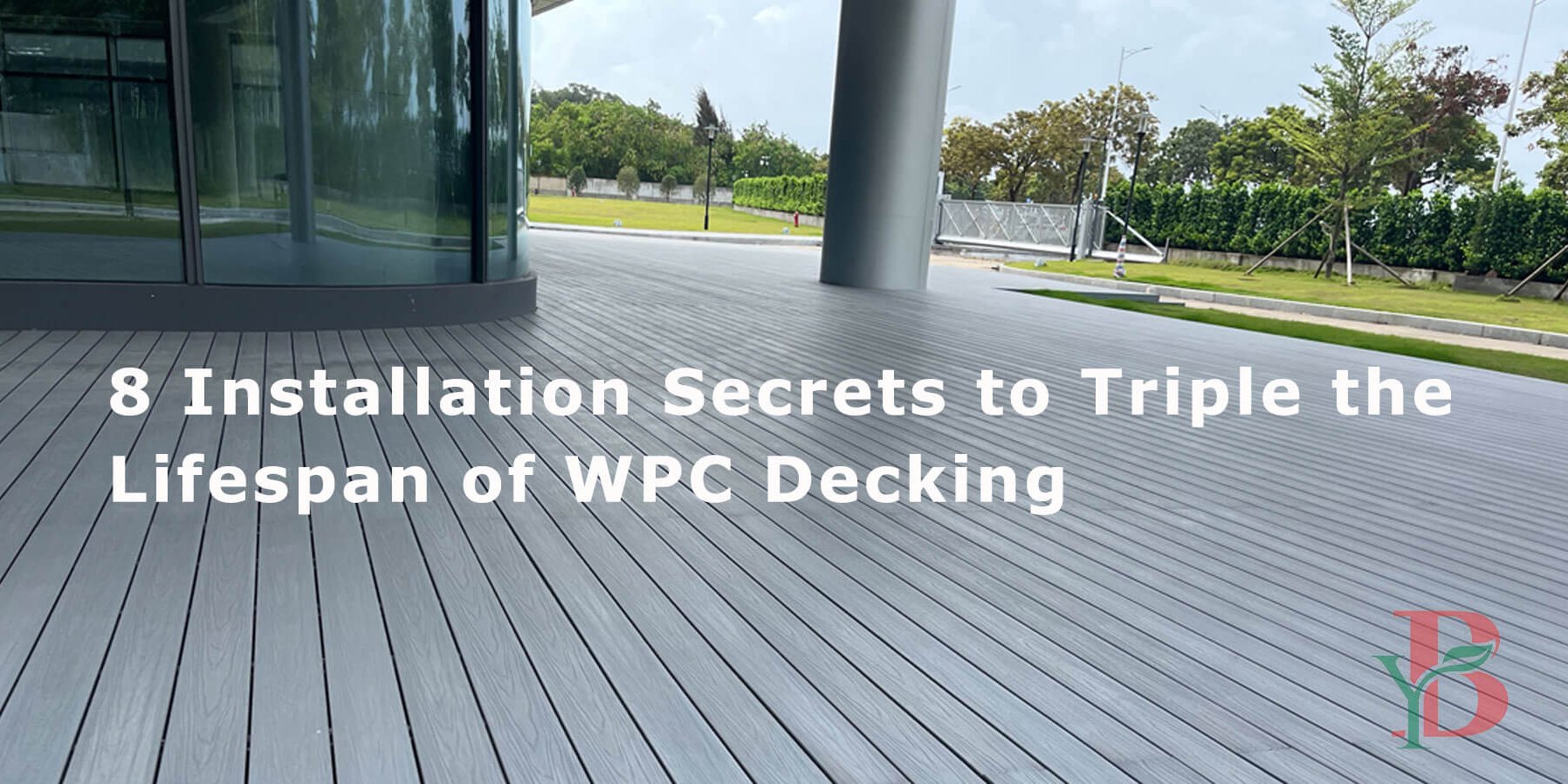

Wood-Plastic Composite (WPC) decking has become a popular choice for balconies, terraces, and courtyards due to its “wood-like appearance without the need for painting” and durability. Many homeowners believe that purchasing high-quality WPC decking solves all problems. However, some installations remain as good as new after 10 years, while others suffer from warping, loosening, cracking, water pooling, and blackening within just two years.

So, where does the problem lie?

In over 70% of failure cases, the cause is not the material itself but improper WPC decking installation!

Drawing on years of experience in the outdoor WPC industry, these 8 crucial WPC decking installation secrets can triple the lifespan of your WPC decking. These often-overlooked details act as invisible switches controlling your deck’s longevity. Mastering these professional WPC decking installation tips will ensure your outdoor deck not only withstands weathering and servers you beautifully for over a decade.

Secret 1: Achieve a Proper Drainage Slope

•Why? Standing water is the enemy of WPC decking, leading to mold, discoloration, and accelerated aging. Proper drainage is fundamental in any successful WPC decking installation.

•How?

o Define the Slope: During joist installation, create a 1%-2% slope (a drop of 1-2cm per meter) toward the drainage direction.

o Precise Execution: Use a string line from the highest to the lowest point to guide joist leveling and fixation.

o Test and Verify: Conduct a water test after installation to ensure water flows away quickly and smoothly without pooling.

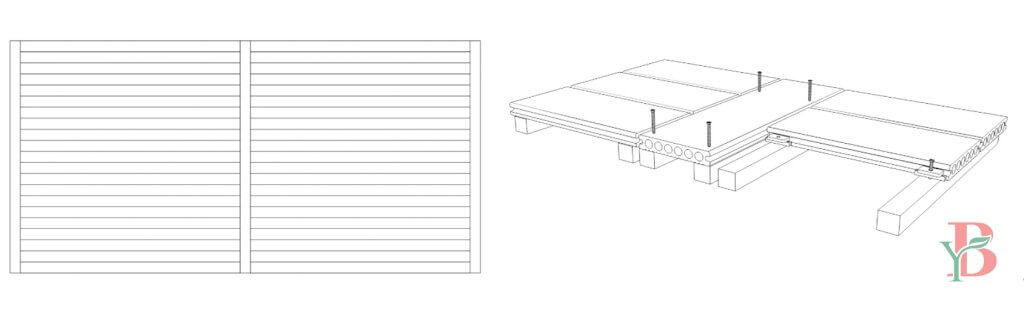

Secret 2: Scientifically Set Joist Spacing

•Why? The joists are the “framework” of the decking. If the spacing is too wide, the deck will sag, make noise, and warp.

•How?

o General Specifications: The center to center spacing of joists for most WPC decking should be ≤ 30cm (300mm).

o Advanced Options:

Decking thickness ≥ 25mm and high density:

The spacing can be widened to 35cm (confirm load-bearing capacity with the manufacturer).

Decking thickness < 20mm or special areas like balconies:

Strongly recommend reducing to 25cm.

Cantilevered Sections (e.g., deck edges):

Further reduce joist spacing or add additional support.

✏️ Material Recommendation: Prioritize aluminum or stainless-steel joists for rust resistance and durability.

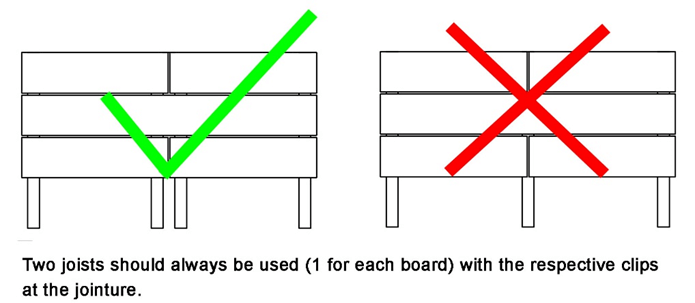

Secret 3: Standardize End-Joint Installation

•Why? Improper end-joint handling during WPC decking installation can lead to shrinkage, detachment, and other issues.

•How?

o Independent Support: Ensure each decking board end is independently supported by a joist. Never allow two board ends to share a single joist.

o Double Joist Structure: Use a double-joist structure at end joints and secure with separate clips.

o Avoid Stress Concentration: All fasteners should be installed on independent joists to avoid stress concentration.

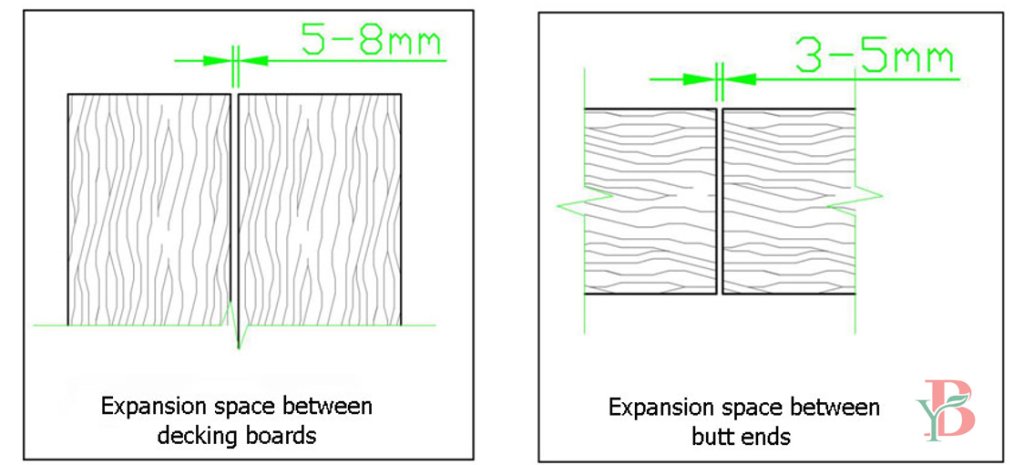

Secret 4: Leave Proper Expansion Gaps

•Why? WPC expands and contracts with temperature changes! Insufficient gaps during WPC decking installation can cause buckling, deformation, and even cracking or edge bursting when the decking expands.

•How?

o Around Walls/Fixed Objects: Leave at least 8-12mm gaps (adjust based on decking length and local temperature variations; larger gaps for greater temperature differences).

o End-Joints Between Boards: Leave 3-5mm gaps between board ends.

o Side-Joints Between Boards: Leave 5-8mm gaps to accommodate the dimensions of specialized clips.

✏️ Pro Tip: Unpack the decking and let it acclimate to the installation environment for 48 hours before installation.

Secret 5: Use Segmented Installation

•Why? WPC is affected by temperature and humidity changes, causing thermal expansion and contraction. Large continuous installations can lead to stress buildup, causing overall warping, corner lifting, uneven expansion gaps, or local deformation. Proper WPC decking installation use segmented installation to divide large areas into smaller sections, releasing stress and enhancing stability and durability.

•How?

o Divide the Installation Area: Limit each section to ≤ 6 meters (adjust based on local climate and temperature variations; shorter segments for greater differences).

o Use Breaker Boards as Dividers: Split large areas into smaller independent sections.

o Set Expansion Gaps: Leave 5-8mm expansion gaps between sections (on both sides of the breaker board). Increase gap width if installing in extreme temperatures (e.g., midsummer or midwinter).

o Reinforce Structural Support: Add extra transverse support under breaker boards to ensure stability. Ensure each section’s ends are firmly supported by joists.

o Optimize Drainage: Each segmented area should have its own drainage slope to prevent water accumulation at expansion gaps.

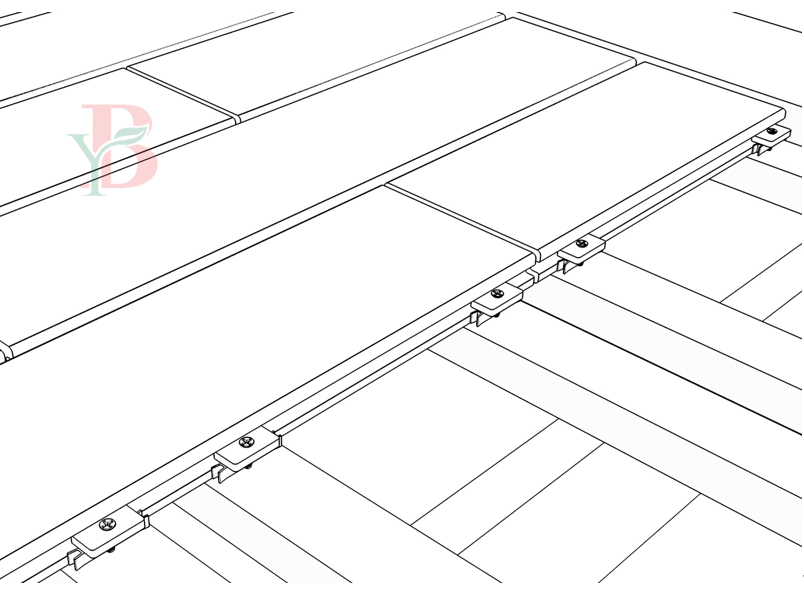

Secret 6: Use Professional Fasteners

•Why? WPC decking clips or screws ensure stability and facilitate easy replacement.

•How?

WPC-Specific Clip Systems:

*Achieve a “nail-free surface” for enhanced aesthetics.

*Materials: Plastic, aluminum, or stainless steel.

*Easy installation and convenient single-board replacement.

Anti-Corrosion Screws (Face-Fixing Method):

*High fixation strength, suitable for load-bearing areas.

*Must use stainless steel countersunk self-drilling screws.

*Ensure corrosion resistance to prevent rust.

o Pre-Drilling: Pre-drill holes before installation to prevent splitting, especially in cold weather.

o Ensure the fastening system matches the decking brand and model to avoid connection issues due to size discrepancies.

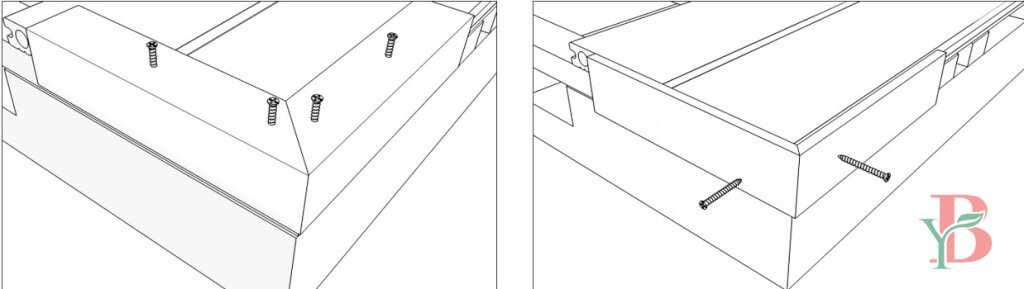

Secret 7: Professional Edge Detailing

•Why? Edges are the most vulnerable parts of and WPC decking installation. Poor finishing affects aesthetics and can lead to lifting, cracking, dirt accumulation, and tripping hazards. Careful edge treatment enhances installation quality, extends lifespan, and ensures long-term beauty and safety.

•How?

o Use L-shaped Edge Trim: Select L-shaped WPC or aluminum edge trim, securely fixed with screws at approximately 500mm intervals.

o Use Straight Board Edge Cover: Fixed the straight board edge cover with screws from the side at approximately 500mm intervals.

o Cut Same Decking for Edge Cover: Vertically cut the same decking material to form an L-shaped edge and then fix it.

o Stair Edges: Use specially designed WPC staircase boards.

Secret 8: Key Maintenance After Installation

•Why? Proper maintenance after installation is essential to prevent common issues and keep your WPC decking looking and performing its best.

•How?

Cleaning

- Immediate Cleaning: Sweep away surface debris and dust immediately after installation.

- Regular Sweeping: Regularly sweep to remove leaves, mud, and other debris.

- Stubborn Stains: Use neutral cleaning agents and soft brushes for stubborn stains.

- Avoid using strong acidic or alkaline cleaners or steel wool to prevent damage to the deck surface.

Ventilation

- Keep the Deck Dry: Maintain ventilation to keep the decking dry.

- Check for Water Accumulation: Especially in humid environments or after rain, check for water accumulation under the decking.

- Ensure Good Ventilation: Ensure good ventilation under the decking to prevent mold growth.

Heavy Objects and Protection

- Avoid Long-term Placement of Heavy Objects: Avoid placing heavy objects on the decking for extended periods immediately after installation.

- Lift Furniture Gently: Lift furniture when moving it to avoid dragging.

- Prevent Sharp Objects: Prevent sharp objects from directly impacting the deck surface.

Regular Inspection

- Comprehensive Check: Inspect the deck a few months post-installation and annually at season changes.

- Check Screws and Clips: Check if screws are loose and if clips have fallen off.

- Ensure Proper Drainage: Ensure proper drainage and address small issues promptly.

Conclusion

Good Materials + Good Craftsmanship = True “Long-Term Value”

Mastering these 8 expert WPC decking installation secrets will dramatically improve the durability and appearance of your outdoor WPC decking. Proper installation techniques such as correct drainage slope, joist spacing, expansion gaps, and professional fasteners, combined with thoughtful maintenance, can triple the lifespan of your deck, ensuring it remains a beautiful and functional outdoor space for over a decade.

Bongywood Wood Plastic Composite

Explore our range of Bongywood WPC materials for your decking project, and feel free to contact us for more information, expert guidance, or any inquiries. Let us assist you in creating your ideal outdoor living space.

Guangdong Bongywood New Building Materials Co.,Ltd. is a professional manufacturer specializing in the R&D, production and sales of WPC (Wood Plastic Composite) materials, our products include: composite decking, capped composite decking, WPC Wall Panel, WPC Railing & Fencing, WPC Pergola & Gazebo, WPC Chairs & Bench, WPC Flower Planter Pots etc.