In the world of outdoor construction, finding a material that balances natural beauty with rugged durability used to be a challenge. Enter WPC material (Wood Plastic Composite—an innovative material that blends the timeless look of wood with the high-performance resilience of plastic.

This composite material is gaining popularity in various industries due to its unique properties and environmental benefits. Whether you are a homeowner planning a new deck or a contractor looking for sustainable building solutions, this guide covers everything you need to know about WPC.

What is WPC and How is it Made?

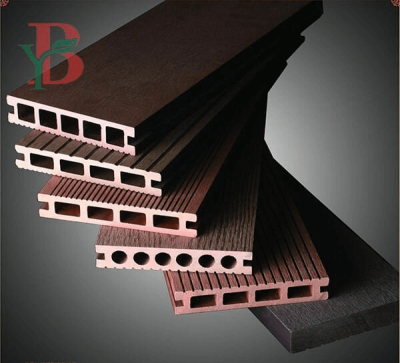

WPC (Wood Plastic Composite) is a hybrid material composed of wood fibers (such as wood flour or bamboo dust) and thermoplastics like Polyethylene (PE), Polypropylene (PP), or Polyvinyl Chloride (PVC).

To achieve higher performance specifications for specific applications, additives such as colorants, reinforcing agents, and lubricants are integrated into the mix.

During manufacturing, these components are combined above the melting temperature of the polymers and then extruded into various shapes and profiles. The result is a dense, heavy-duty material that resists moisture and decay far better than traditional timber.

Material Composition of Bongywood WPC Material

The basic composition of Bongywood WPC is centered on sustainability, utilizing recycled wood fibers and recycled HDPE.

This can be represented as:

5 Key Benefits of Using WPC Material in Outdoor Projects

Why is WPC rapidly replacing pressure-treated wood? Here are the top five reasons:

High Durability & Weather Resistance

Unlike natural wood, WPC does not absorb water easily. This prevents the common "wood trio of doom": rotting, warping, and splitting.

Low Maintenance Requirements

Forget the annual ritual of sanding or staining. WPC requires no chemical treatments. A simple wash with soap and water is enough.

Aesthetic Versatility & Style

Modern WPC offers 3D Embossed grains. From "Charcoal Gray" to warm "Teak," it provides consistent, premium color and texture.

Eco-Friendly & Sustainable

Bongywood WPC is made from 90% recycled materials. Choosing WPC helps reduce landfill waste and preserves our forests.

Enhanced Safety

WPC is splinter-free and engineered with anti-slip textures, making it a priority for families with children or pets.

Fast & Easy Installation

Designed with hidden clip systems, WPC allows for faster installation than traditional timber, saving time and labor costs.

Things to Consider When Choosing WPC (Cost vs. Performance)

- Initial Investment: WPC has a higher upfront cost than cheap pine or cedar, although its long-term durability and low maintenance can offset initial costs.

- Heat Retention: Like most dense materials, WPC can get warm in direct sunlight. If your project is in a high-heat area, we recommend choosing lighter colors.

- Structural Limits: WPC is perfect for surfaces but should not be used for primary structural “load-bearing” beams. Always use treated timber or steel for the sub-frame.

Uses and Applications of Bongywood WPC Material

The versatility of Bongywood WPC allows it to be used across diverse architectural landscapes:

WPC decking is ideal for patios, gardens, and poolsides due to their weather resistance and slip-resistant surface.

Bongywood WPC offers various decking options such as: Classical Composite Decking, Co-extrusion Decking/Capped Composite Decking, 3D Embossed Decking etc.

WPC Wall Cladding provides a modern facade while protecting the building from UV rays.

WPC material is secure, durable and zero maintenance, won’t rot like traditional fences. They are widely used for the preparation of fences for gardens and other outdoor fencing purposes.

WPC Benches & Chairs:

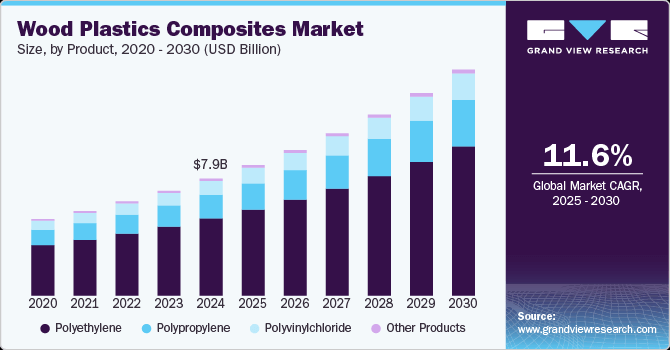

Future Outlook: WPC Market Trends 2025-2030

The global Wood Plastic Composite market is projected to grow at a CAGR of 11.6% through 2030. As environmental regulations tighten and the demand for “green” building materials rises, WPC is transitioning from a “premium alternative” to the “industry standard” for residential and commercial outdoor spaces.

Conclusion: Why Choose Bongywood WPC?

Guangdong Bangying New Building Materials Co., Ltd. (Bongywood) specializes in the R&D and production of high-performance WPC materials.

- Climate Resilient: Performance-tested from -40°C to 60°C.

- Eco-Friendly: Made from sustainable, recycled materials.

- Low Maintenance: No staining, painting, or rotting—ever.

From decking to pergolas, we provide the strength your project deserves.

Ready to upgrade your outdoor space? We offer expert consultations and free quotes for all your project needs. [Contact Us Today for a Free Sample Kit]