The global wood-plastic composites market is estimated to reach $13470.41 million by 2028, growing at a CAGR of 11.87% in terms of revenue during the forecast period. In terms of volume, the global wood plastic composites market is expected to reach 16503.63 kilotons by 2028, growing at a CAGR of 10.43% during the forecast period. The base year considered for the study is 2019, and the estimated period is between 2020 & 2028.

Primary factors propelling the growth of the global wood plastic composites market are:

- Rising demands from building and construction applications

- Prohibition on the use of arsenic toxins, chromium and toxins copper

- Growing demands for recyclable materials in the automotive industry

- Rising demands for PVC-capped decking products

- Concerns regarding Environment

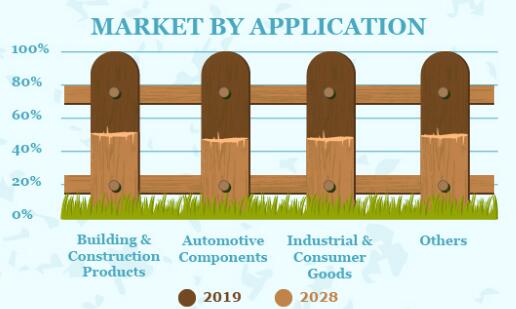

The rising demand from the building and construction applications is one of the important factors driving growth in the wood-plastic composites market. Building and construction applications hold the largest share in the wood-plastic composites market as traditional wood is one of the most widely used components in this sector. Wood plastic composites consist of thermoplastic, wood fiber, and other materials, namely lubricants, pigments, foaming agents, and blowing agents, which are used in fewer quantities. Wood-plastic composites are known for their high durability and long shelf life than raw wood. They are also considered to be eco-friendly because they are mostly prepared using sawmill by-products and recycled plastic.

However, the lack of rigidity and impact of heavy load, lack of well-defined quality standards, product limitations in certain applications, weight reduction of WPC products, and low preference for recycled products, are profoundly restricting the wood plastic composites market growth globally.

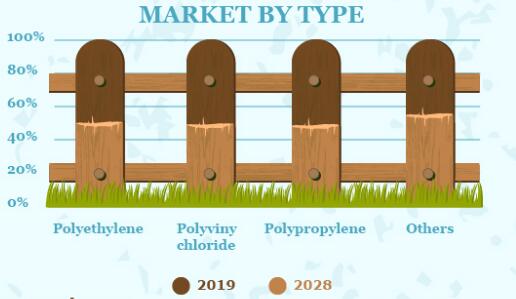

In 2019, around 55.46% of the revenue share was captured by the Polyethylene (PE) wood plastic composites. PE wood plastic composites are useful in making exterior products for rough applications and high performance. Polyethylene wood plastic composites are utilized in manufacturing molding strips, lumber, wall cladding, furniture materials, flooring, hollow boards, hollow filler sections, and profiles.

Market by type:

- Polypropylene (PP)

- Polyvinylchloride (PVC)

- Polyethylene (PE)

- Other Types

Market by application:

- Industrial & Consumer Goods

- Automotive Components

- Building & Construction Products

- Other Applications

Geographically, the global wood plastic composites market has been segmented on the basis of four major regions, which includes:

- North America: the United States and Canada

- Europe: the United Kingdom, Germany, France, Italy, Russia, Poland, Belgium, and the Rest of Europe

- Asia Pacific: China, India, Japan, South Korea, Australia & New Zealand, ASEAN, and the Rest of Asia Pacific

- Rest of World: Latin America, the Middle East & Africa

In terms of geography, North America dominated the wood plastic composites market with a revenue share of 46.46% in 2019. The key countries in the region include the U.S. and Canada. Large and widening population base with increasing consumption, rapid urbanization, and shift of customer preference towards wood plastic composites products are the factors driving the growth of the North American wood plastic composites market.

Though the adoption of wood plastic composites in the Asia Pacific as compared to North America is low at present, the outlook for the market in the region is positive. The Asia Pacific regional market majorly covers the market development of China, Japan, India, and the countries from the Rest of Asia Pacific. China held the largest share in terms of revenue of about 61.87% of the Asia Pacific wood plastic composites market in 2019. A large and dominant manufacturing sector in China has resulted in wood plastic composite materials being used to increase the durability and shelf life of the products. Also, the rising demand from countries, namely India and Japan, due to its increasing application in outdoor applications and demand from the building & construction industry, is driving the overall Asia Pacific wood plastic composites market.

Key findings of the global wood plastic composites market are:

- There is a rising demand for wood plastic composites in emerging economies of Asia Pacific, Latin America, and Africa.

- The injection molding is the new method used for the production of a wood plastic composite in the global market.

- There is an increase in the use of recyclable raw materials, which is boosting the wood plastic composites market.

From: Inkwood Research

Guangdong Bongywood New Building Materials Co., Ltd. is a professional manufacturer specializing in the R&D, production, and sales of WPC (Wood Plastic Composite) materials, our products include composite decking, capped composite decking, WPC Wall Panel, WPC Railing & Fencing, WPC Pergola & Gazebo, WPC Chairs & Bench, WPC Flower Planter Pots, etc.

Leave a Reply