Wood Plastic Composite (WPC) is an innovative material that combines the natural aesthetics of wood with the durability of plastics. This composite material is gaining popularity in various industries due to its unique properties and environmental benefits. In this article, we will explore what WPC is, its advantages, applications, and considerations for its use.

What is WPC?

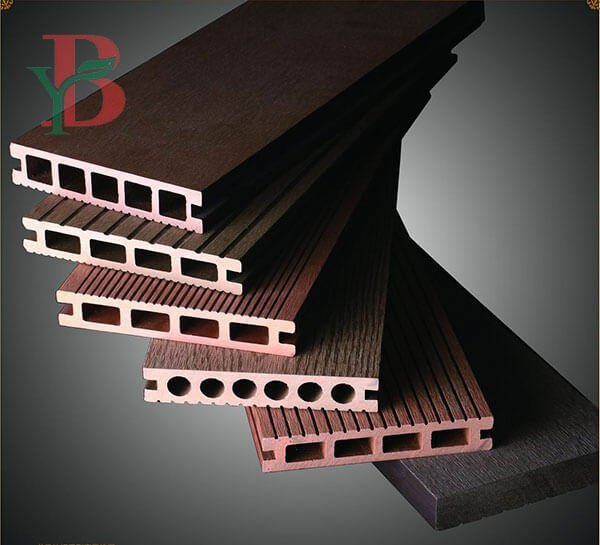

Wood Plastic Composite (WPC) is a composite material made from a blend of wood fibers and thermoplastic, such as polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC). The wood and thermoplastics are usually compounded above the melting temperature of the thermoplastic polymers and then further process to make various WPC processed to make various WPC products. This combination results in a material that retains the appearance of wood while offering superior resistance to moisture, insects, and decay.

Additives, such as colorants, reinforcing agents, and lubricants can be added to achieve a higher level of specification for the intended product’s use. Because of the composite’s unique composition, wood plastic composite can be manipulated to assume a wide array of shapes and dimensions, including arched and bent shapes. There is wide range of uses and applications of WPC material in outdoor deck, railings, fences, cladding, park benches and outdoor landscape and so on.

Benefits of WPC

High Durability

WPC is resistance to rot, decay, insects, and moisture damage. Built to withstand extreme weather conditions.

Low Maintenance

No regular staining or painting required. Only basic cleaning with water and mild soap maintains pristine appearance.

Aesthetic Appeal

Available in multiple colors and authentic wood textures. Combines natural wood beauty with modern material benefits.

Eco-Friendly Build

Made from recycled wood flour and plastics. Helps reduce environmental impact while preserving natural resources.

Wide Applications

Perfect for decking, cladding, fencing and outdoor structures. Adaptable to diverse architectural applications.

Things to Consider When Choosing WPC

While WPC material offers many benefits, there are some considerations to keep in mind:

- Cost: WPC can be more expensive than traditional wood, although its long-term durability and low maintenance can offset initial costs.

- Heat Retention: WPC can absorb heat, making it hot to the touch in direct sunlight. This may be a consideration for outdoor applications in hot climates.

- Limited Structural Use: WPC is not suitable for structural applications where high strength is required, such as load-bearing beams.

- Chemical Properties: The wood component within WPC does impact some positive attributes compared to plastic, the inherent problems with wood (moisture sorption and susceptibility to mold and decay) remain. So the second Co-extrusion WPC(also called capped) emerged, compared with the traditional WPC, the Co-extrusion WPC is better at mold and mildew, less water-absorption & less rotten etc.

Characteristics of Bongywood WPC Material

There are various characteristics of Bongywood WPC board which are listed below:

- Appearance of natural wood, but less timber problems;

- Easy to install with low labor cost;

- Resistant to moisture, rot and termites;

- No painting or staining required, low maintenance;

- Resistant to temperatures between –40°C to 60 °C;

- Non- toxic chemicals or preservatives.

- Durable quality: high bending strength, more impact resistance, low expansion rate & low water absorption rate;

- Environmental friendly material, Ten WPC Boards = Save One Tree

Uses and Applications of Bongywood WPC Board

WPC has a wide variety of applications:

Outdoor WPC Decking:

WPC decking is ideal for patios, gardens, and poolsides due to their weather resistance and slip-resistant surface.

Bongywood WPC offers various decking options such as: Classical Composite Decking, Co-extrusion Decking/Capped Composite Decking, 3D Embossed Decking etc.

WPC Wall Cladding:

WPC Railing & Fencing:

As the material is secure and durable,they are widely used for the preparation of fences for gardens and other outdoor fencing purposes.

WPC Pergola Gazebo:

WPC Benches & Chairs:

Markets

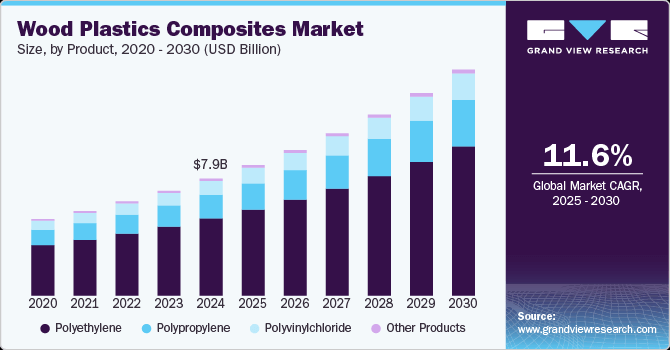

The Wood Plastic Composites market share has been growing rapidly. The main drivers for WPC acceptance are the perceived improved performance and appearance attributes over existing products such as treated wood decking. Stricter regulations on the use of chemicals in building materials, such as the phasing out of CCA treated lumber for residential decking and the desire for “green” building materials (WPCs can use waste wood and recycled plastics) have also contributed to greater acceptance of WPCs by builders and homeowners.

Two-thirds of the WPCs produced are decking and railing products. Additional potential applications for WPCs include cladding, siding, roofing, residential fencing, picnic tables, benches, landscape timber, patios, gazebos and walkways, and playground equipment.

The global wood plastic composite (WPC) market is set to experience remarkable growth in the coming years. The global wood plastic composite market forecast size was estimated at USD 7.97 billion in 2024 and is projected to grow at a CAGR of 11.6% from 2025 to 2030. The market is driven by the rising demand for sustainable construction materials along with an increase in renovation and repair activities in the residential sector across the globe.

Conclusion

Wood Plastic Composite (WPC) is a versatile and sustainable material that offers numerous advantages over traditional wood and plastic products. Its durability, low maintenance, and aesthetic appeal make it an excellent choice for a variety of applications, particularly in outdoor settings. As the demand for eco-friendly materials continues to grow, WPC is poised to play a significant role in the future of construction and design.

Bongywood Wood Plastic Composite

Guangdong Bangying New Building Materials Co., Ltd. is a professional manufacturer specializing in the R&D, production, and sales of WPC (Wood Plastic Composite) materials, our products include composite decking, capped composite decking, WPC Wall Panel, WPC Railing & Fencing, WPC Pergola & Gazebo, WPC Chairs & Bench, WPC Flower Planter Pots, etc. Contact us today for professional expertise and a free quote.